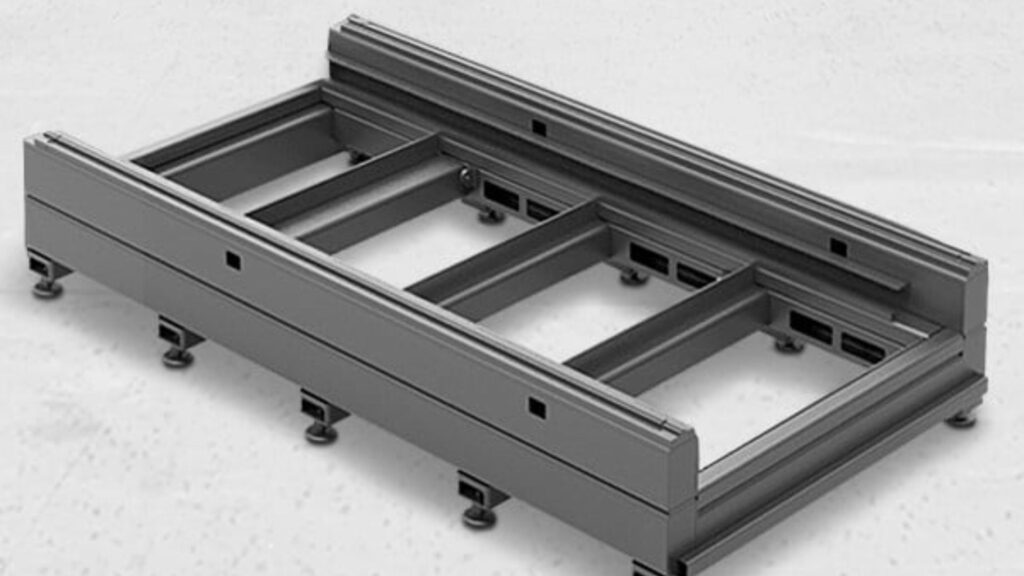

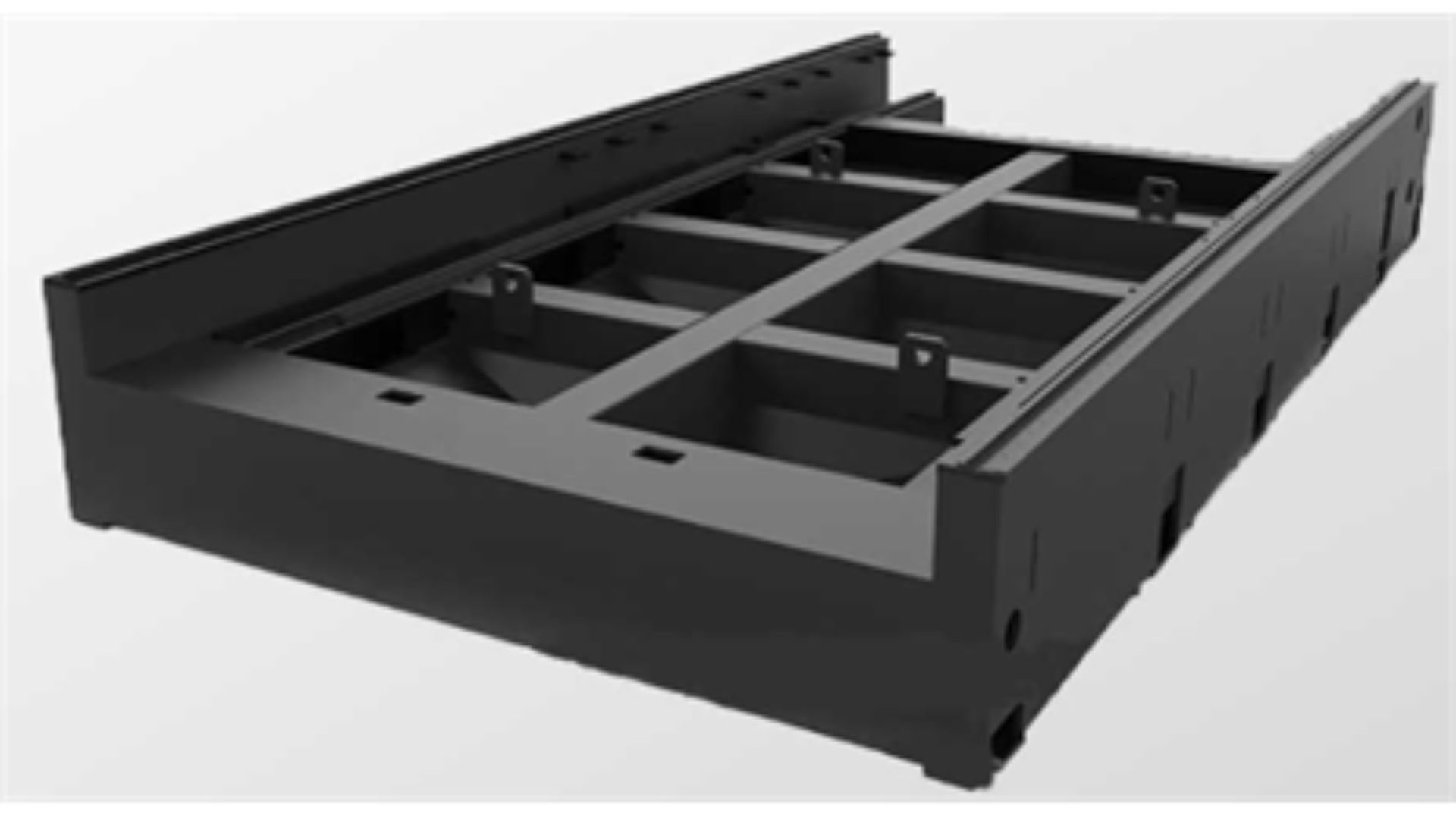

When it comes to ensuring the smooth and efficient operation of heavy machinery, selecting the right inertia base is crucial. Inertia bases play a critical role in minimizing vibration and noise, protecting both the machinery itself and the surrounding environment. However, with a wide variety of options available on the market, choosing the ideal inertia base can be a daunting task. Fear not! This comprehensive guide will walk you through the key factors to consider when selecting the perfect inertia base for your machinery.

- Weight and Size of the Machinery

One of the first considerations when choosing an inertia base is the weight and size of the machinery it will support. Inertia bases are designed to absorb and dissipate vibrations generated by machinery, so it’s essential to select a base that can accommodate the weight and dimensions of your equipment effectively. Be sure to carefully assess the specifications of your machinery and choose an inertia base with sufficient load-bearing capacity and surface area to provide stable support.

- Vibration Isolation Requirements

Different types of machinery may have varying vibration isolation requirements based on factors such as operating frequency, amplitude, and environmental conditions. For machinery with high vibration levels or sensitive components, it’s essential to select an inertia base with superior vibration isolation properties. Look for bases equipped with resilient isolators or damping materials that can effectively attenuate vibrations and prevent them from transferring to the surrounding structure.

- Environmental Factors

Consider the environmental conditions in which the machinery will operate when selecting an inertia base. Factors such as temperature fluctuations, humidity levels, and exposure to corrosive substances can affect the performance and durability of the base over time. Choose a base constructed from materials that are resistant to corrosion, moisture, and temperature extremes to ensure long-term reliability and stability in any environment.

- Installation Requirements

Before purchasing an inertia base, carefully assess the installation requirements and constraints of your facility. Determine whether the base needs to be bolted to the floor, placed on a concrete pad, or installed using other mounting methods. Additionally, consider factors such as space limitations, accessibility for maintenance, and compatibility with existing infrastructure to ensure a smooth and hassle-free installation process.

- Customization Options

In some cases, off-the-shelf inertia bases may not fully meet the unique requirements of your machinery or facility. Look for manufacturers that offer customization options, such as adjustable height, special mounting configurations, or additional damping features. Customized inertia bases can be tailored to fit your specific needs and provide optimal performance for your equipment.

- Quality and Reliability

Last but certainly not least, prioritize quality and reliability when selecting an inertia base for your machinery. Choose reputable manufacturers known for producing high-quality products that meet industry standards for performance and durability. Investing in a reliable inertia base may require a higher upfront cost, but it will pay off in the long run with reduced maintenance, extended equipment lifespan, and improved operational efficiency.

Conclusion

Selecting the right inertia base for your machinery is essential for ensuring smooth operation, minimizing vibration and noise, and protecting both equipment and personnel. By considering factors such as weight and size requirements, vibration isolation properties, environmental conditions, installation needs, customization options, and quality standards, you can confidently choose an inertia base that meets your specific needs and delivers reliable performance for years to come.