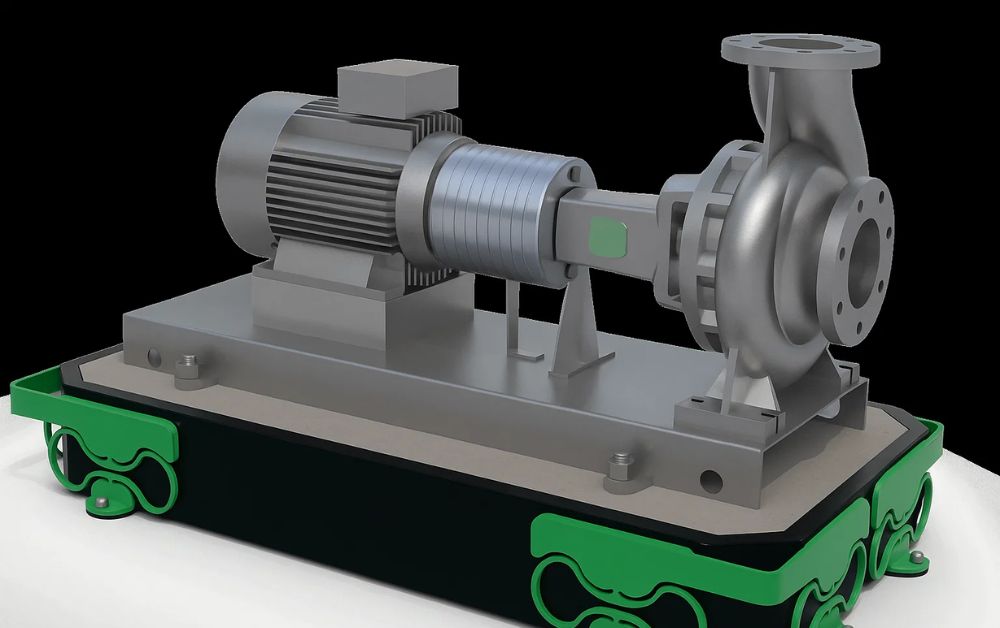

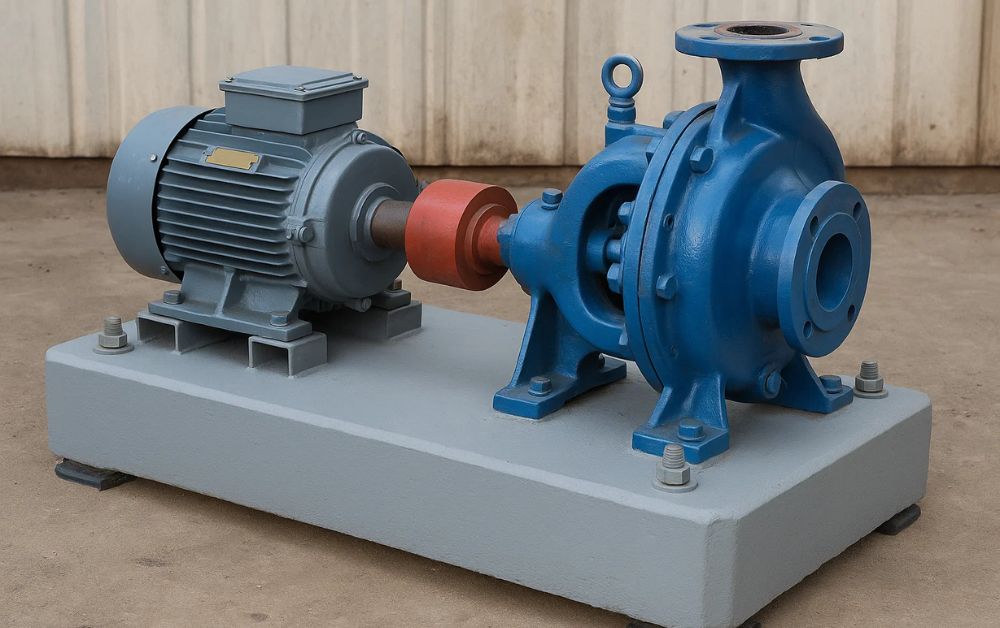

Installing an inertia base pump is crucial for reducing vibration and noise in mechanical systems. These pumps are commonly used in HVAC systems, water supply setups, and industrial machinery to ensure smooth operation while minimizing operational noise. However, improper installation can lead to inefficiencies, increased maintenance costs, and even equipment failure. In this blog, we’ll discuss five common mistakes in inertia base pump installation and provide practical tips on how to avoid them.

1. Ignoring Proper Leveling

One of the most frequent mistakes during inertia base pump installation is failing to properly level the base. An uneven base can cause misalignment of the pump, leading to excessive vibration, wear on moving parts, and reduced efficiency.

How to Avoid:

- Use a precision level to ensure the base is perfectly horizontal.

- Verify alignment with the pump’s shaft before securing it in place.

- Make adjustments with shims or leveling bolts to achieve a stable and even surface.

2. Inadequate Vibration Isolation

The primary purpose of an inertia base pump is to reduce vibration. Installing the pump directly on a rigid surface without considering isolation can transfer vibrations to the surrounding structure, causing noise and potential damage to nearby equipment.

How to Avoid:

- Install vibration-damping pads or mounts under the base.

- Ensure the isolation material is rated for the pump’s weight and operational frequency.

- Periodically inspect and replace worn damping materials to maintain optimal performance.

3. Improper Bolt Tightening

Another common mistake is uneven or incorrect tightening of mounting bolts. Over-tightening can warp the base, while under-tightening may allow movement, both of which can affect pump performance.

How to Avoid:

- Follow the manufacturer’s torque specifications for all bolts.

- Use a cross-pattern tightening sequence to ensure even pressure distribution.

- Recheck bolts after the first few hours of operation to ensure they remain secure.

4. Neglecting Pipe Support and Alignment

Piping connected to an inertia base pump exerts stress on the pump casing if not properly supported. Misaligned pipes can transmit vibrations, cause leaks, or place unnecessary strain on the pump bearings.

How to Avoid:

- Ensure all connected pipes are properly supported and aligned.

- Use flexible connectors or expansion joints to absorb minor misalignments and thermal expansion.

- Double-check that the piping does not pull or twist the pump after installation.

5. Skipping Operational Testing

Finally, many installations are considered complete without performing operational testing. Failing to test the inertia base pump can lead to unnoticed vibration, noise, or alignment issues that worsen over time.

How to Avoid:

- Conduct a test run at operational speed before finalizing installation.

- Monitor vibration levels, noise, and temperature.

- Make necessary adjustments based on observations to ensure smooth and quiet operation.

Additional Tips for Successful Inertia Base Installation

- Follow Manufacturer Guidelines: Always adhere to the manufacturer’s instructions for installation, alignment, and maintenance.

- Regular Maintenance: Schedule routine checks for alignment, vibration, and damping materials.

- Environmental Considerations: Install pumps in areas free from excessive moisture, dust, and temperature extremes to prolong equipment life.

- Training: Ensure installation personnel are trained and aware of the specific requirements of inertia base pump systems.

Conclusion

Installing an inertia base pump correctly is essential for ensuring efficiency, reducing noise, and prolonging the life of your mechanical system. Avoiding common mistakes such as improper leveling, inadequate vibration isolation, incorrect bolt tightening, poor pipe alignment, and skipping operational testing can save time, money, and frustration. For those seeking professional guidance and premium-quality acoustic solutions, Perfect Acoustics shines as a trusted provider, offering expert advice and top-tier products that optimize the performance of inertia base pump installations while minimizing operational noise and vibration.